- Medical & Pharmaceutical industry

- Medical industry

- X-ray inspection system

- Waygate Technologies

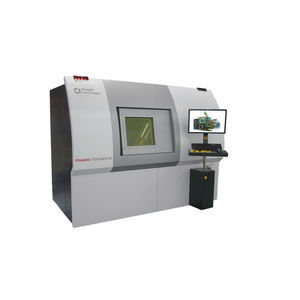

X-ray inspection system Phoenix Microme|x Neo automatedelectronic

Add to favorites

Compare this product

Characteristics

- Type

- X-ray

- Operational mode

- automated, electronic

Description

The Phoenix Microme|x Neo and Nanome|x Neo provide high-resolution 2D X-ray technology, PlanarCT and 3D computed tomography (CT) scanning in one system.

With innovative engineering coupled with ultra-high positioning accuracy, Phoenix Microme|x Neo and Nanome|x Neo are ideally suited for industrial X-ray electronics inspections in process and quality control for greater productivity, failure analysis for the increased safety and quality of your products, and R&D where innovations are born. Both enableautomated X-ray inspection (AXI) of electronic components - such as semiconductors, PCBs, electronic assemblies, sensors and lithium-ion batteries - in industrial, automotive, aviation and consumer electronics industries.

Non-destructive electronics inspection starts here

Innovative and unique features and an extremeCT high positioning accuracy make both the phoenix MicromeIx 160 and 180 neo and the NanomeIx 180 neo the effective and reliable solution for a wide spectrum of 2D and 3D offline inspection tasks: R&D, failure analysis, process and quality control.

The Phoenix|x-ray X|act inspection software offers easy to program CAD based µAXI ensuring automated inspection in the micrometer range. Another unique benefit is Waygate Technologies rich options of flat panel detectors, from highly dynamic DXR 250RT with active cooling to large size DXR S100 Pro with brilliant resolution. There's always a perfect matching image chain serving your particular application.

Highlights

Benefits

Brilliant live inspection images due to high dynamic Waygate Technologies' DXR digital detector array

VIDEO

Catalogs

Other Waygate Technologies products

Radiographic Testing and Industrial CT Solutions

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.