- Medical & Pharmaceutical industry

- Medical industry

- X-ray inspection system

- Waygate Technologies

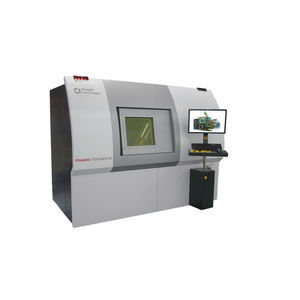

X-ray inspection system Phoenix V|tome|x C450automatedmedicalcompact

Add to favorites

Compare this product

Characteristics

- Type

- X-ray

- Operational mode

- automated

- Applications

- medical

- Other characteristics

- compact

Description

Inspect and measure large samples with high precision and throughout

The Phoenix V|tome|x C is a high performance compact industrial 450 kV minifocus CT system for inspection and 3D metrology of a wide applications range such as large light metal castings, turbine blades, AM parts etc.

Waygate Technologies’ patented Scatter|correct technology automatically removes most scatter artifacts from the CT volume. This technological advancement provides image quality like that achieved with conventional fan-beam scanning but at speeds up to 100 times faster.

Industrial CT Inspection of large, high absorbing samples starts here

Our Phoenix V|tome|x C is a compact 450 kV CT system with the largest possible scan volume and usable specimen weight especially for production and production-related areas such as production lines and quality assurance laboratories in battery manufacturing, in foundries and in aerospace – a flexible combination of semi-automated, non-destructive inspection and VDI 2630-1.3 specified 3D metrology.

The Phoenix V|tome|x C comes standard with our exclusive 4 MP Dynamic 41|200 next-generation photodiode design industrial X-ray detector. It provides 10x increased sensitivity relative to the state of the art 200 µm pixel size DXR detectors producing 2-3x cycle time increase without image quality impact, making inspections and measurements more efficient and productive. Compared to 16-bit detectors, the optimized 14-bit technology offers the highest efficiency with a dynamic range of 10000:1 and thus saves time in use and also generates less noise in the image.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Waygate Technologies‘s catalogsOther Waygate Technologies products

Radiographic Testing and Industrial CT Solutions

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.