- Products

- Weiler Engineering

Extrusion line

Add to favorites

Compare this product

Description

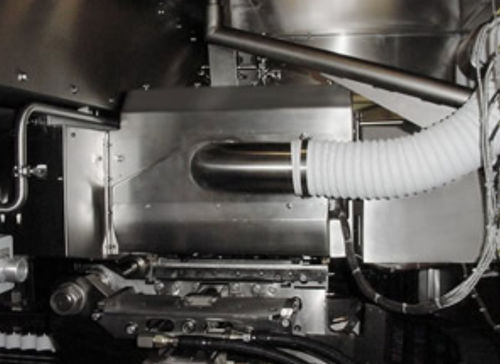

A two-component package is available to enhance the environmental process conditions within the extrusion zone of the ASEP-TECH® machine. HEPA filtered air is supplied to an enclosed area encompassing the parison head and mold transport area of the ASEP-TECH® machine. Airflow to this area is monitored with a flow sensor and alarmed to ensure consistent operation. Control of this “zone of protection” reduces effects due to potential changes in the machine room environment.

A secondary stainless steel collection shroud encloses the parison head and is coupled to an exhaust system with an external blower to be mounted outside the cleanroom within 30’ (9 meters) of the ASEP-TECH® machine.

This combination system helps ensure that typical non-viable particle counts in this area will meet US FDA Class 10,000 under dynamic conditions.

Catalogs

No catalogs are available for this product.

See all of Weiler Engineering‘s catalogsOther Weiler Engineering products

Blow Fill Seal Machine Optional Accessories

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.