- Dental

- Dental laboratory

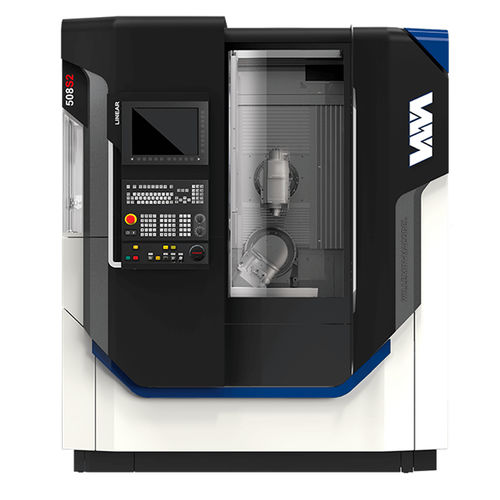

- CAD/CAM milling machine

- Willemin-Macodel SA

- Products

- Catalogs

- News & Trends

- Exhibitions

CAD/CAM milling machine 508S2dentalmedical industry5-axis

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- CAD/CAM

- Applications

- dental, medical industry

- Number of axes

- 5-axis, 6-axis

- Configuration

- benchtop

- Power

10,000 W, 15,000 W

- Height

2,220 mm

(87.4 in)- Depth

2,210 mm

(87.01 in)- Weight

4,700 kg

(10,361.73 lb)

Description

The 508S2 is a machining center with 5 simultaneous axes designed to machine complex prismatic workpieces. It benefits from "Full Linear" technology – all the linear and rotary axes are equipped with direct drive motors. Thanks to its dynamic performance and very stable temperature, the 508S2 is a highly productive machine for manufacturing high added-value parts requiring great precision and premium quality surface finishes.

The 508S2 machining center is fitted with a vertical powered spindle for milling operations at up to 42,000 rpm, and a dual rotary divider for turning operations on the C axis at up to 4000 rpm. It includes many customized features, including a tool magazine offering up to 96 positions, or custom-developed robotization. This makes the 508S2 a real multi-process machining center.

Benefiting from the latest technological developments and Willemin-Macodel's comprehensive expertise in high-precision machining on 5 simultaneous axes, the 508S2 is perfect for cutting-edge industries such as watchmaking, jewelry, medical, dental, aerospace and high-precision mechanical sub-contracting.

Direct drive of the X, Y and Z axes by linear motors, feed rate 60 m/min

Direct drive dual divider with a 180 mm diameter plate (turning up to 4000 rpm as an option)

Fanuc 31 i-B5 or Heidenhain TNC 640 NC control console with 15" screen

Tool magazine with 48-position quick changer (72 or 96-position magazine as an option)

Various automation/robotization systems, loading or unloading of workpieces or pallets (can be adapted on the right-hand side of the machine)

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.