- Dental

- Dental laboratory

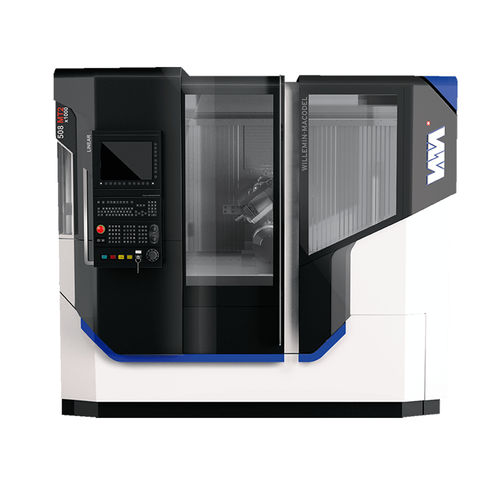

- CAD/CAM milling machine

- Willemin-Macodel SA

- Products

- Catalogs

- News & Trends

- Exhibitions

CAD/CAM milling machine 508MT2 X1000dentalmulti-axisspindle

Add to favorites

Compare this product

Characteristics

- Type

- CAD/CAM

- Applications

- dental

- Number of axes

- multi-axis

- Number of spindles

- spindle

- Spindle speed

42,000 rpm

(263,894 rad.min-1)- Power

24,000 W, 34,000 W

- Height

2,220 mm

(87.4 in)- Depth

2,210 mm

(87.01 in)- Weight

5,500 kg

(12,125.42 lb)

Description

The 508MT2 X1000 is a multi-process machining center dedicated to machining complex parts from Ø 65 mm bar stock. It is equipped with a swiveling powered spindle fitted on a B axis and a high-precision A axis divider/spindle enabling turning operations up to 3000 rpm.

The 508MT2 X1000 machining center offers exceptional flexibility and productivity. Its innovative pickup turret with 2 usable positions, including a counter-spindle and a precision vice, enables all secondary operations to be performed. It is the turning turret with 12 motorized positions which really sets the 508MT2 X1000 apart. This allows the machine to simultaneously machine with both the milling motor spindle and the turning turret, with no compromises. This allows you to optimize your machining ranges, enabling production time to be halved in the most favourable scenarios.

Benefiting from the latest technological developments and Willemin-Macodel's comprehensive expertise in high-precision machining from bar stock, the 508MT2 X1000 is perfect for cutting-edge industries such as watchmaking, medical, aerospace and high-precision mechanical sub-contracting.

Direct drive of the X, Y and Z axes by linear motors

Fanuc 31 i-B515 NC control console, 15" screen

Tool magazine with 48-position quick changer (72-position magazine as an option)

Pickup turret with 2 usable positions (counter-spindle and vice), fitted on the U axis, 520 mm travel

Turning turret with 12 motorized positions, speed 12,000 rpm, fitted on a Z2 axis with 300 mm travel and a X2 axis with 150 mm travel

Various bar feeder systems for short or long bars (can be adapted on the left-hand side of the machine)

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.