- Products

- CAM software module

- Zirkonzahn

Simulation software module Nesting mock-upCAMfor dental laboratories

Add to favorites

Compare this product

Characteristics

- Function

- simulation, mock-up, CAM

- Applications

- for dental laboratories

Description

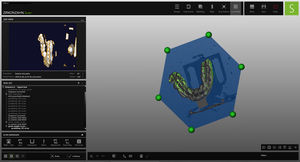

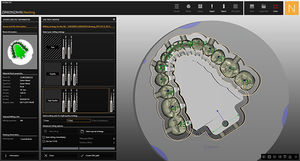

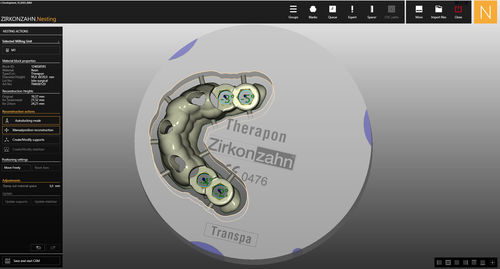

Axis-oriented nesting programme for the ideal positioning of dental restoration data in the milling blank.

All existing blanks will be saved in one library. This allows, at any time and from an economic point of view, to select the smallest possible blank and to fully benefit from already used blanks.

Automatic blank registration via webcam – during the registration of the blank, the error potential is minimized because typing errors are excluded. In addition, the quality management is improved, because batch numbers can be tracked.

Automatic docking – if the restoration is positioned outside the blank, it is automatically repositioned by the software at the ideal place on the brink of the blank.

Parallel Speed Calculation – all milling steps of a work can be calculated simultaneously with a considerable reduction of time.

Simultaneous calculation of several blanks – the milling paths of several jobs in different blanks can be calculated simultaneously.

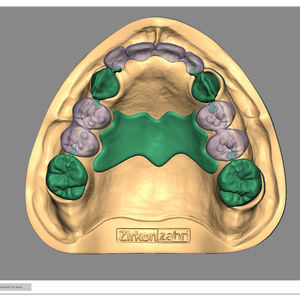

Coloured display of the materials with gradient shading as well as rendering function with a pre-visualisation of the milling result.

Upgraded CAD/CAM STL-Import software module – with surface analysis for the identification and manual modification of important parameters such as preparation lines, screw channels etc.

STL Raw Import – for the milling of individual titanium abutments which have been designed with a design software of another producer (not Zirkonzahn.Modellier).

Collision Detection – reports possible collisions of the tool with the orbit or the blank.

Mechanical finishing of the friction of secondary structures which will be fixed on telescopic crowns.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.