CoCr dental material Sinternitfor implant systemsfor ceramic veneering

Add to favorites

Compare this product

Characteristics

- Type

- CoCr

- Applications

- for implant systems, for ceramic veneering

Description

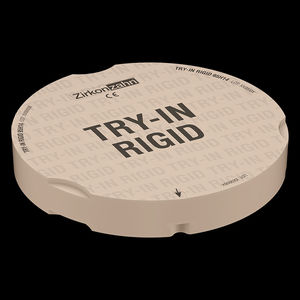

The Cobalt-Chrome blanks (non-precious metal) are highly pre-compressed and slightly sintered, which enables the milling of all dental restorations. Thanks to the fact that the raw material has a shrinkage factor of just 7%, its torsional stability during the sintering process is very high. Like this, all milled dental restorations (full arch bridges, single crowns, metal structures, telescopes, bars, attachments) can be sintered with total lack of stresses.

Properties at a glance:

High performance cobalt-chromium alloy

100% deformation resistant - no distortions or stresses in the metal structure

No impurities in the metal structure

High flexural strength trough seamless material bond and smooth surfaces (final density > 98 %)

High edge stability

Your CAD/CAM system does not have to be upgraded

Oxygen-free sintering in the Zirkonofen 700 Ultra-Vakuum sintering furnace with high vacuum and special sintering adapter (no additional furnace is required) or in the Sinterofen 300S sintering furnace.

Sintering without shielding gas

Due to perfect temperature distribution in the furnace, manufacturing up to 14-unit restorations is possible

Milling time depending on milling unit: ca. 15 minutes

Electroplating to reduce the grey value of zirconia secondary structures

Faster than the casting technique

Sinternit (cobalt-chrome alloy) for the production of single crowns, bridges, bars and telescopic crowns. It is suitable for monolithic restorations as well as structures of up to 14 units for veneering with ceramics.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Nordental 2025

30 Oct - 01 Nov 2025 Lillestrom (Norway) Hall Hall B, NOVA Spektrum - Stand B01-09

More information

Related Searches

- Zirkonzahn dental material

- Zirkonzahn dental restoration material

- Implant abutment

- Titanium implant abutment

- Straight implant abutment

- Internal implant abutment

- Zirkonzahn resin dental material

- Zirkonzahn dental prosthesis dental material

- Viewer software

- Modeling dental material

- Zirkonzahn dental crown material

- Zirkonzahn ceramic dental material

- Dental bridge material

- Biocompatible dental material

- Angulated implant abutment

- Wax dental material

- Casting dental material

- Zirkonzahn dental CAD/CAM material

- Zirkonzahn translucent dental material

- Zirkonzahn dental software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.