- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

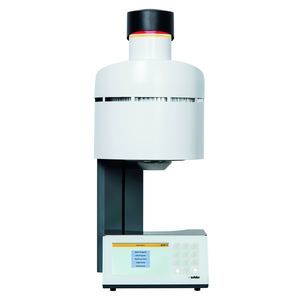

Drying oven VARIOPRESS 330.eflamepressfor dental laboratories

Add to favorites

Compare this product

Characteristics

- Function

- drying, flame, press

- Applications

- for dental laboratories

- Designed for

- for ceramics

- Configuration

- benchtop

- Temperature range

1,200 °C

(2,192 °F)

Description

The ADVANCED PRESS™ process ensures a uniform temperature distribution from the temperature sensor of the pressing furnace to the inside of the press ring. Pressing always takes place within the ideal temperature range for pressing lithium disilicate. As a result, this technology ensures perfect surfaces, minimal reaction layers and extremely short pressing times.

The ingenious software and the lift technology enable a linear cooling process when in TTC mode: In this programme, the user determines the freely selectable cooling rate after firering. Cracks in the ceramic or the dreaded „chipping“ are a thing of the past.

The electronically controlled pressing power regulation recognizes the required pressing forces during the working process, depending on the geometry of the objects to be pressed. In the case of diff erent volumes or thicknesses, the VARIOPRESS 330 regulates the pressing power automatically and dynamically during the entire working process. Finishing the pressing process too early with the consequent defects on the pressed objects is nearly impossible.

A virtual sensor adjusts the lift position based on the temperature in the fi ring chamber and automatically ensures an ideal and constant pre-drying temperature of about 150°C on the entire surface of the tray. This process prevents the ceramic from cracks or bubbles.

If the power goes out, PFC is activated! Once power is restored the oven operation is returned to the point of interruption.

After the successful registration of your VARIO PRESS 330 pressing furnace in the service area of our Zubler homepage, you have access to our extensive database.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ZUBLER‘s catalogsRelated Searches

- Dental material

- Restoration dental material

- Dental prosthesis dental material

- Dental crown material

- Heating furnace

- Ceramic dental material

- Dental bridge material

- Drill

- Benchtop furnace

- Dental laboratory workstation

- Dental handpiece

- Drying furnace

- Electric drill

- Dental laboratory furnace

- Zubler dental laboratory dust suction unit

- Metal dental material

- High-temperature furnace

- Zubler dust suction unit with filtration system

- Zubler compact dust suction unit

- Dental laboratory press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.